Dosing corrosive products with PeriBest Pumps

Dosing corrosive products is always a challenge. Many technologies are unable to provide safe solutions for these types of applications.

Progressive cavity pumps have numerous metal parts in contact with the product, which makes it very difficult and costly to make a corrosion-resistant version.

Moreover, diaphragm dosing pumps have problems in high suction applications (double-wall tanks), in applications with products that generate gases, such as sodium hypochlorite, or with products that crystallise, such as caustic soda.

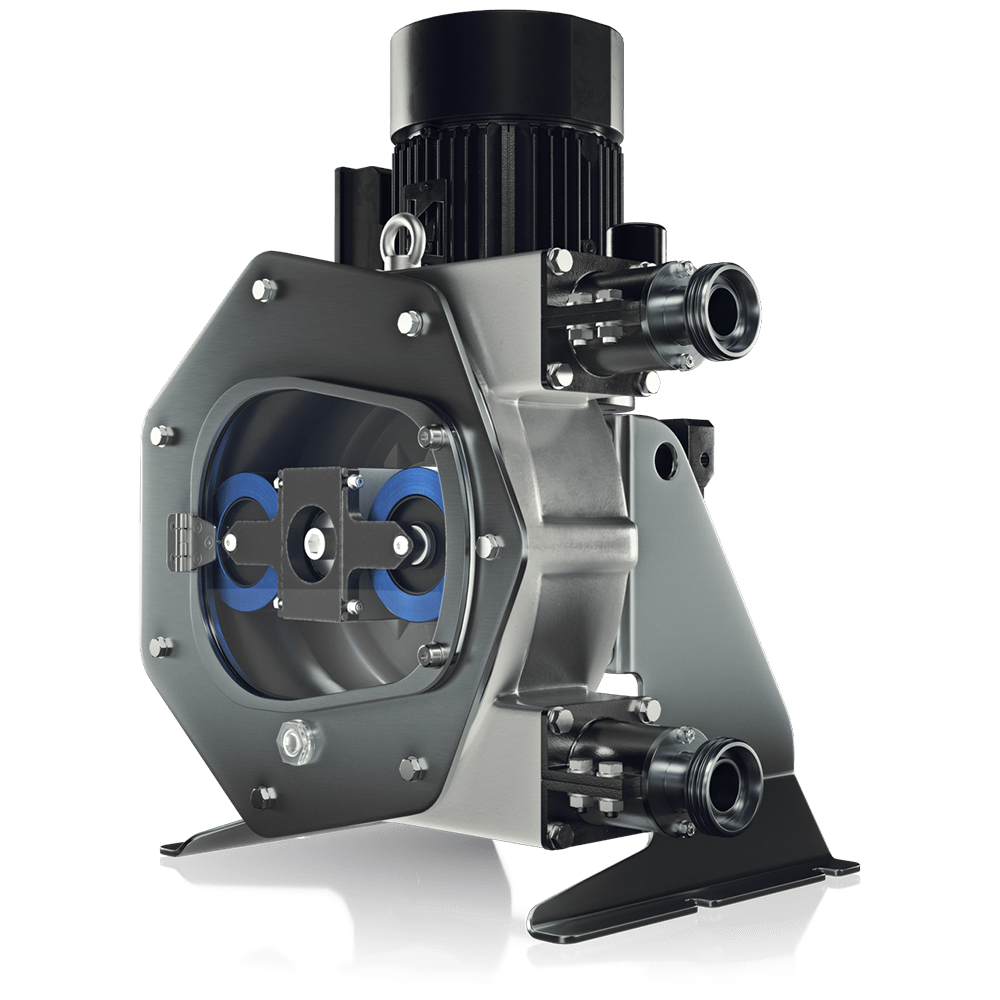

The PeriBest peristaltic pumps only have 2 elements in contact with the fluid: the hose and the connections, which makes it easy to find chemically compatible elements. Having no valves, a high suction capacity and the ability to pump gases, they are ideal for applications in which dosing pumps encounter problems (products that generate gases, products that crystallise, high suction applications).

In its Chemical version, the PeriBest pump includes the necessary changes to produce a unit that is fully protected and resistant to highly corrosive acids and all kinds of difficult chemicals.

Basically, this version consists of:

– Latest-generation peristaltic hose in NR, EPDM or Hypalon®.

– Pump body and front cover coating in TEFZEL®

– Plastic connections in polypropylene or PVDF.

– Hose leakage detector.

– Pump and roller lip seals in EPDM.

– Corrosion-resistant rollers.

– Drainage of leaked product within the pump body.

These specifications give a fully corrosion-resistant, robust, heavy-duty pump at a very competitive pric